Blogs, Product Installation Guide

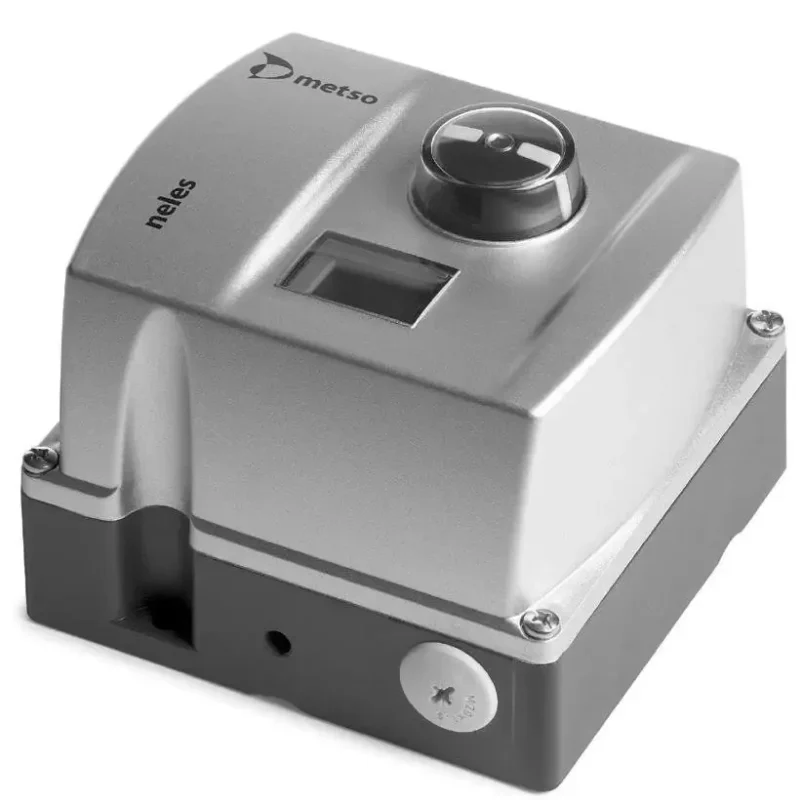

Neles ND9102HN Positioner – Precision Flow Control by Metso

Introduction

In modern industrial automation, accurate valve control is essential for maintaining process efficiency, product quality, and energy savings. Among the most trusted solutions in the market, the Neles ND9102HN positioner by Metso (Neles) stands out for its exceptional precision, reliability, and robustness. Designed for demanding process industries, this advanced positioner ensures that control valves operate smoothly and accurately under varying process conditions.

Whether it’s used in oil and gas, chemical plants, power generation, or pulp and paper applications, the Neles ND9102HN brings intelligent control to every flow operation.

1. Overview of the Neles ND9102HN Positioner

The Neles ND9102HN is a pneumatic or electro-pneumatic valve positioner developed by Metso (Neles) for use with linear and rotary actuators. It converts a control signal into a precise valve position, ensuring accurate control of process flow.

This positioner belongs to the ND9000 series, a line of intelligent valve controllers known for advanced diagnostics, field communication, and superior control performance.

Key Technical Highlights

-

Type: Smart electro-pneumatic positioner

-

Model: ND9102HN

-

Communication Protocols: HART / Foundation Fieldbus (optional)

-

Input Signal: 4–20 mA DC

-

Output Signal: Pneumatic control for actuator movement

-

Mounting: Suitable for both rotary and linear actuators

-

Enclosure Rating: IP66 / NEMA 4X

-

Operating Temperature: -40°C to +80°C

-

Explosion-proof Options: Available for hazardous environments

The ND9102HN integrates seamlessly with Metso’s automation systems and third-party DCS solutions, making it a flexible choice for modern process control.

2. Working Principle

The Neles ND9102HN positioner receives an electrical input signal (4–20 mA) from a process controller or DCS. Based on this signal, it adjusts the air supply to the actuator, positioning the valve precisely to achieve the desired flow rate.

This feedback-based operation ensures that any deviation between the setpoint and actual valve position is corrected immediately. The result is highly accurate, stable, and responsive valve control, even under challenging process conditions such as fluctuating pressures or high vibration.

3. Key Features and Benefits

a) Exceptional Accuracy and Stability

The ND9102HN uses advanced control algorithms and feedback sensors to maintain precise valve positioning. This ensures tight process control, minimal hysteresis, and improved product consistency.

b) Intelligent Diagnostics

One of the standout features of the ND9000 series is its self-diagnostic capability. The ND9102HN continuously monitors valve and actuator performance, detecting issues like friction, air leaks, or stem packing wear. These diagnostics help reduce unplanned downtime and support predictive maintenance strategies.

c) Robust Design for Industrial Environments

Built with corrosion-resistant materials and sealed against dust and moisture (IP66/NEMA 4X), the ND9102HN performs reliably even in harsh process environments such as refineries, offshore platforms, and chemical plants.

d) Easy Integration and Communication

With HART compatibility, the ND9102HN can communicate with any HART-enabled control system, allowing operators to configure, calibrate, and monitor it remotely. Optional Foundation Fieldbus and PROFIBUS variants provide flexibility for modern digital plants.

e) Low Air Consumption and Energy Efficiency

The pneumatic system is engineered for minimal air loss, reducing energy consumption and operating costs over time. This makes it both cost-effective and environmentally friendly.

4. Applications in Process Industries

The Neles ND9102HN is widely used across multiple sectors due to its versatility and precision.

Oil & Gas Industry

Used in control valves for gas flow regulation, fuel handling, and separator control, the ND9102HN ensures precise actuation even in explosive environments (ATEX/IECEx certified models available).

Chemical and Petrochemical Plants

Accurate dosing and pressure control are essential in chemical production. The ND9102HN offers fine-tuned valve movement, ensuring safety, product uniformity, and compliance with process requirements.

Power Generation

In power plants, reliable steam and feedwater control are critical. The ND9102HN delivers stable valve control under high temperature and vibration conditions.

Pulp & Paper Industry

Metso’s heritage in the pulp and paper sector makes the ND9102HN a preferred solution for pulp flow, bleaching, and chemical dosing systems—providing consistent control in high-moisture environments.

5. Installation and Maintenance

Simple Setup

The ND9102HN supports auto-calibration, making commissioning fast and straightforward. Once installed, the positioner automatically adjusts to match actuator characteristics and control signal parameters.

Maintenance Efficiency

Thanks to its built-in diagnostics, operators can monitor valve health in real time, identifying maintenance needs before failures occur. This reduces downtime and extends the life of the actuator and valve assembly.

Remote Configuration

Through HART communication, settings can be modified remotely without opening the housing—enhancing safety in hazardous areas.

6. SEO Keyword Suggestions

To optimize visibility on search engines like Google, include the following keywords throughout your webpage or article:

Neles ND9102HN, Metso ND9102HN, Neles valve positioner, Metso positioner, ND9102HN positioner, ND9000 series positioner, HART valve controller, electro-pneumatic positioner, Neles intelligent positioner, valve automation, process control valve, Metso automation solutions.

7. Advantages of Choosing the Neles ND9102HN

| Feature | Benefit |

|---|---|

| Smart diagnostics | Predictive maintenance and reduced downtime |

| High accuracy | Enhanced product quality and process efficiency |

| Rugged construction | Reliable performance in harsh conditions |

| Easy integration | Compatible with HART, Fieldbus, and DCS systems |

| Low air consumption | Reduced operational costs |

| Flexible mounting | Works with both linear and rotary actuators |

8. Conclusion

The Neles ND9102HN by Metso (Neles) represents the perfect blend of intelligence, reliability, and precision in valve control. With its advanced diagnostics, robust construction, and seamless communication features, it ensures smooth process operation across industries.

For engineers and plant operators seeking a dependable, energy-efficient, and easy-to-maintain valve positioner, the ND9102HN is a proven choice that delivers long-term value and performance.