Blogs

ABB PHARPSFAN03000 Fan Explained: Core Functions and Real Industrial Applications

ABB PHARPSFAN03000 Fan Explained: Core Functions and Real Industrial Applications

The ABB PHARPSFAN03000 fan plays a vital role in modern industrial environments because automation systems continue to demand stable and efficient cooling solutions. As factories upgrade equipment and transition toward higher-density control modules, the need for dependable airflow management becomes more important than ever. Therefore, engineers, maintenance teams, and procurement specialists show strong interest in understanding how the PHARPSFAN03000 works, why it matters, and where it fits within complex automation architectures. This article explores all core elements of the fan while providing practical insights into real application scenarios. It also introduces reliable supply support from Wuhan Yuli Automation Technology Co., Ltd. through its official platform www.wuhanyuli.com.

1. What the ABB PHARPSFAN03000 Fan Is and Why It Matters

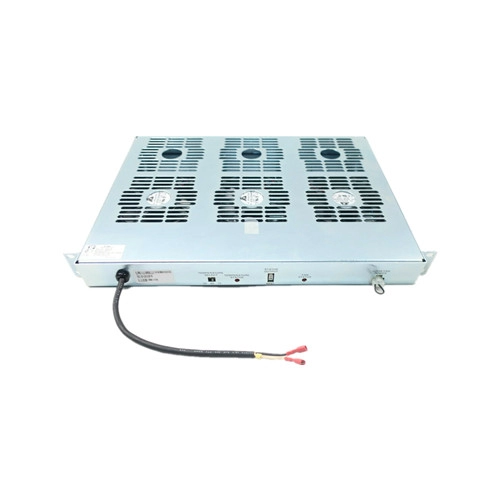

The ABB PHARPSFAN03000 cooling fan supports heat management inside industrial control cabinets. As automation modules operate continuously, they generate thermal loads that can increase internal temperatures and threaten long-term reliability. Because modern DCS and PLC environments operate nonstop, every degree of extra heat affects CPU cards, power modules, and I/O hardware.

Therefore, the PHARPSFAN03000 improves stability by circulating concentrated airflow through the cabinet and directing heat away from sensitive circuit areas. Moreover, the fan creates a consistent thermal balance, so engineers can maintain predictable system performance even in demanding environments. This combination of structural simplicity and operational importance makes the PHARPSFAN03000 a fundamental accessory for ABB Bailey systems and other compatible setups.

2. Core Functional Design of the PHARPSFAN03000

The PHARPSFAN03000 follows a compact and optimized mechanical structure that balances airflow volume, noise control, and durability. Although the fan looks simple at first glance, each part contributes to stable long-term performance.

2.1 High-Efficiency Airflow Path

The fan forces cool air through a steady forward direction so heat dissipates uniformly. Consequently, modules inside the cabinet maintain equal temperature distribution. This airflow strategy reduces hot spots, protects system boards, and helps maintain constant heat removal even under heavy loads.

2.2 Robust Motor Assembly

The motor inside the fan uses industrial-grade materials that tolerate long operational cycles. Because ABB automation systems often run 24/7, the fan’s motor design prioritizes endurance and consistency. Furthermore, friction-reduction features support smooth rotation, so performance remains steady across thousands of hours of continuous use.

2.3 Reinforced Housing and Stable Mounting

The PHARPSFAN03000 includes a strong enclosure that minimizes vibration and protects internal components. Engineers can mount the fan in narrow cabinet zones without stability issues. In addition, the housing resists dust and environmental contaminants, which makes installation safer in older facilities or harsh industrial sites.

2.4 Optimized for ABB Cabinet Ecosystems

Although the fan can integrate into various systems, it performs best in ABB Bailey cabinet configurations. The airflow pattern aligns with ABB cabinet layouts, so thermal distribution becomes more uniform. Therefore, engineers who replace old components or upgrade systems often choose the PHARPSFAN03000 to ensure predictable thermal behavior.

3. Why Engineers Choose the PHARPSFAN03000

Because cooling affects nearly every aspect of performance, engineers appreciate several advantages from this model.

3.1 Predictable and Long-Term System Stability

A consistent cooling environment reduces thermal stress on electronic components. Consequently, modules such as power supplies, processor cards, and communication boards operate with lower failure risks.

3.2 Reduced Maintenance Costs

When the fan stabilizes the thermal environment, hardware degradation slows down. Therefore, maintenance teams face fewer emergency repairs and replacement cycles. This cost advantage becomes significant in large-scale systems with numerous cabinet assemblies.

3.3 Simplified Installation Compatibility

The PHARPSFAN03000 fits easily into ABB systems without modification. Engineers appreciate the time savings, especially during shutdown-sensitive maintenance tasks where every minute matters.

3.4 Dependable Quality Backed by Industrial Standards

ABB components follow strict manufacturing standards. Consequently, the PHARPSFAN03000 maintains consistent operational quality across different production batches. Because automation systems rely heavily on stability, this reliability offers strong assurance to field engineers.

4. Real Industrial Application Scenarios

Because cooling matters across a wide variety of operational settings, the PHARPSFAN03000 appears in many industrial environments. Each scenario highlights a different aspect of the fan’s importance.

4.1 Power Plants

Power generation facilities operate large ABB Bailey control systems that run continuously. Because these systems generate considerable thermal load, the PHARPSFAN03000 ensures stable air circulation through densely packed control cabinets. Consequently, the plant minimizes downtime risks and maintains stable operation across long maintenance cycles.

4.2 Petrochemical and Refining Plants

Harsh industrial environments often expose automation equipment to heat, dust, and corrosive elements. Because the PHARPSFAN03000 uses durable materials, it withstands long-term operation in these facilities. Moreover, stable airflow protects I/O banks and power cards from thermal stress.

4.3 Pulp and Paper Industry

Production lines in paper plants operate heavy mechanical equipment that generates heat and humidity. Therefore, cabinet fans play a critical role in keeping control hardware dry and cool. The PHARPSFAN03000 offers a reliable solution that stabilizes ABB system cabinets under these conditions.

4.4 Metallurgy and Steel Manufacturing

Steel production involves extreme temperatures that affect surrounding control rooms. Consequently, cooling fans inside automation cabinets become essential. The PHARPSFAN03000 supports airflow management that protects temperature-sensitive electronics from heat intrusion.

4.5 Industrial Upgrading and Retrofit Projects

When aging ABB Bailey systems require modernization, engineers frequently replace old fans with PHARPSFAN03000 units. Because the model integrates seamlessly, engineers complete retrofits more efficiently. This compatibility encourages smooth transitions during system upgrade cycles.

5. Best Practices for Using the PHARPSFAN03000

To maximize performance, engineers often follow several operational strategies:

-

Check airflow direction during installation so heat dissipates optimally.

-

Clean dust filters regularly to maintain unobstructed air movement.

-

Monitor cabinet temperature trends so teams can adjust fan configuration if needed.

-

Replace fans proactively instead of waiting for performance decline.

-

Source components from reliable suppliers such as Wuhan Yuli Automation Technology Co., Ltd. to ensure authenticity.

These practices improve long-term performance and decrease unexpected thermal-related issues.

6. Where to Source Original ABB PHARPSFAN03000 Fans

Because authenticity matters in industrial environments, engineers often seek trusted suppliers. Wuhan Yuli Automation Technology Co., Ltd., through its official website www.wuhanyuli.com, provides original ABB automation parts including the PHARPSFAN03000 fan. The company offers global shipping support, technical consultation, and rapid delivery options for time-sensitive maintenance schedules.

Conclusion

The ABB PHARPSFAN03000 cooling fan plays an essential role in protecting industrial automation systems, improving long-term stability, and supporting efficient thermal behavior across diverse industrial applications. Because modern industrial plants operate continuous and high-density automation networks, reliable cooling becomes a foundation for system performance. Therefore, choosing the PHARPSFAN03000 ensures engineers achieve predictable operation, reduced maintenance costs, and smoother system integration. For high-quality sourcing and dependable supply assurance, Wuhan Yuli Automation Technology Co., Ltd. remains a trusted partner for ABB components worldwide.