Blogs

ABB PHARPSFAN03000 vs Industrial Fans: Performance Comparison

ABB PHARPSFAN03000 vs Industrial Fans: Performance Comparison

Introduction to Industrial Cooling Fans

Industrial cooling fans play a critical role in maintaining optimal temperatures for electronic systems, control cabinets, and automation equipment. Among them, the ABB PHARPSFAN03000 has gained recognition for its durability, precise airflow, and energy efficiency. In comparison to other industrial fans, it offers unique advantages that improve system reliability and reduce maintenance requirements. This article explores the performance differences, technical specifications, and operational benefits of the PHARPSFAN03000 relative to competing industrial fans, helping engineers and facility managers make informed decisions for thermal management.

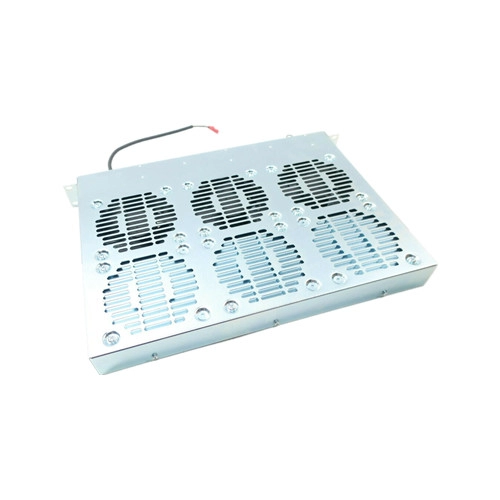

Key Specifications of ABB PHARPSFAN03000

The PHARPSFAN03000 operates at AC 230V, with a frequency of 50/60Hz, and delivers a rotational speed up to 2800 RPM. Its airflow capacity ensures effective cooling for ABB PLCs, HMIs, power supplies, and control panels. Noise emission remains below 55 dB(A), and its compact design allows integration into various enclosures. Additionally, its reinforced motor housing and high-quality blades support continuous operation in high-temperature, vibration-prone, or dusty environments. Built-in safety mechanisms prevent overcurrent or overheating, ensuring long-term reliability.

Comparison with Standard Industrial Fans

Compared to standard industrial fans, the PHARPSFAN03000 offers several distinguishing features. While many generic fans deliver similar airflow, they often lack ABB-specific compatibility, precise RPM control, and low-noise operation. Furthermore, standard fans typically require more frequent maintenance due to lower build quality or insufficient motor protection. The PHARPSFAN03000, in contrast, integrates seamlessly with ABB modules and maintains consistent performance even under high-load conditions, minimizing downtime and operational risk.

Airflow Efficiency and Cooling Performance

One critical difference lies in airflow efficiency. The PHARPSFAN03000 generates stable airflow that evenly distributes cooling throughout control cabinets, preventing hotspots that could damage electronic components. Other industrial fans, while capable of moving air, often create uneven airflow patterns, leading to localized overheating and reduced system reliability. In addition, the PHARPSFAN03000 maintains its performance across a wide range of ambient temperatures, whereas generic fans may experience reduced efficiency in extreme conditions.

Noise and Vibration Levels

Noise and vibration are significant factors in industrial environments. The PHARPSFAN03000 produces minimal noise (<55 dB(A)) and reduces vibration transfer to sensitive electronics. Competing fans often create higher noise levels and mechanical vibrations that can affect performance and accelerate component wear. By maintaining low acoustic output, the PHARPSFAN03000 ensures a safer and more comfortable working environment while preserving the integrity of automation equipment.

Energy Consumption and Operational Cost

Energy efficiency distinguishes the PHARPSFAN03000 from standard industrial fans. Its optimized motor design reduces power consumption while maintaining high cooling performance. In comparison, generic fans may consume more electricity to achieve similar cooling results. Over time, the energy savings from the PHARPSFAN03000 contribute to lower operational costs and support sustainable industrial practices.

Durability and Maintenance Requirements

Durability represents another key advantage. The PHARPSFAN03000 features reinforced blades, high-quality bearings, and a protective motor housing, ensuring extended service life even in harsh environments. Standard industrial fans often require more frequent maintenance due to weaker construction or susceptibility to dust and temperature fluctuations. Additionally, the PHARPSFAN03000 simplifies maintenance with its modular design, allowing easy replacement or inspection without disassembling entire control panels.

Integration with ABB Control Systems

The ABB PHARPSFAN03000 is optimized for ABB PLCs, HMIs, power supply modules, and redundant systems. Its precise airflow control ensures consistent module temperatures, preventing thermal throttling and prolonging component life. Other industrial fans, lacking specific integration, may not provide uniform cooling or may require additional mounting adaptations. The PHARPSFAN03000’s compatibility reduces installation complexity and standardizes cooling solutions across multiple ABB devices.

Reliability and Safety Features

The fan incorporates safety features such as overcurrent protection and automatic thermal shutdown mechanisms. These measures reduce the risk of damage due to electrical faults or excessive heat. Competing fans may lack such protective systems, increasing the likelihood of failures. The reliability of the PHARPSFAN03000 ensures continuous operation in mission-critical industrial environments.

Conclusion: Why PHARPSFAN03000 Outperforms Competitors

In conclusion, the ABB PHARPSFAN03000 surpasses other industrial fans in performance, energy efficiency, noise reduction, durability, and integration with ABB systems. Its advanced design ensures consistent cooling, minimizes maintenance, and extends the life of electronic modules. Industrial operators seeking reliable and efficient thermal management will benefit from adopting the PHARPSFAN03000 across PLCs, HMIs, power modules, and redundant systems. By selecting this fan, facilities achieve improved performance, lower operational costs, and enhanced system safety.