Blogs

ABB NTCL01 Module Usage Tips: Extending Lifespan and Enhancing Reliability

ABB NTCL01 Module Usage Tips: Extending Lifespan and Enhancing Reliability

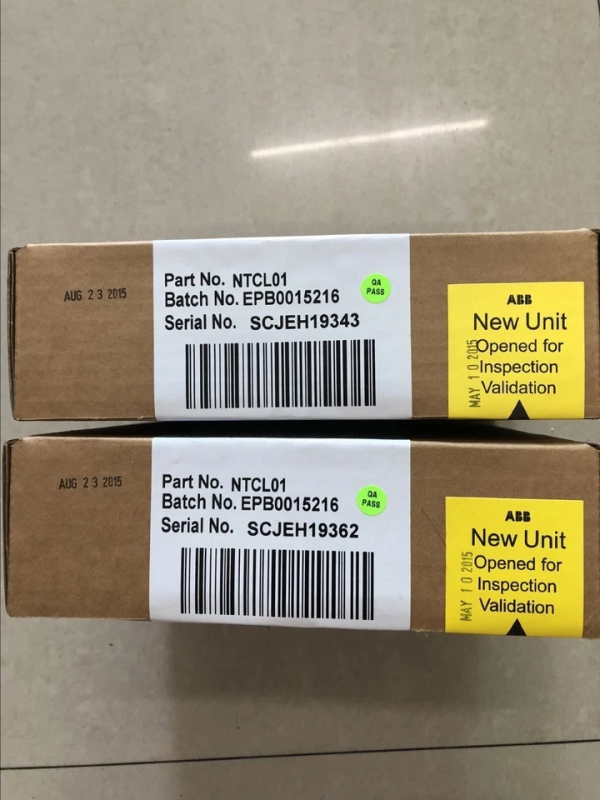

Introduction to ABB NTCL01 Module

The ABB NTCL01 module is a versatile and highly reliable industrial automation component widely used in manufacturing, process industries, and power generation systems. Its advanced features support precise control, monitoring, and communication within automation networks. While the module is engineered for durability, implementing proper usage practices can significantly extend its operational life, enhance reliability, and optimize system performance.

Understanding the Importance of Proper Module Usage

Proper handling and usage of the NTCL01 module are critical to maintaining system efficiency. Incorrect installation, improper maintenance, or environmental stress can reduce the module’s lifespan and affect performance. By understanding key usage strategies, industrial operators can ensure that the NTCL01 continues to provide accurate, reliable control for years to come.

Key Factors Affecting NTCL01 Longevity

Environmental Conditions

Industrial environments can expose the NTCL01 module to vibration, dust, humidity, temperature fluctuations, and electrical interference. Proper protection and placement are essential to safeguard internal components and maintain consistent performance.

Power Quality

Stable power supply is crucial for the module’s health. Voltage spikes, fluctuations, and electrical noise can stress electronic components. Utilizing surge protectors, UPS systems, and proper grounding helps prevent damage.

Load and Signal Management

Ensuring that input and output signals remain within the module’s specified limits reduces stress on contacts and electronic circuits. Overloading can accelerate wear and reduce operational reliability.

Installation Best Practices

Optimal Placement

Position the NTCL01 module away from excessive vibration, heat sources, and moisture. Avoid installing near high-power devices that may generate electromagnetic interference (EMI).

Correct Mounting

Secure the module according to ABB guidelines to prevent mechanical stress and ensure reliable electrical connections. Proper alignment and fastening prevent vibration-induced wear and connector loosening.

Cable Management

Organize cabling to avoid strain on connectors. Use shielded cables for signal lines in electrically noisy environments to prevent interference that could compromise reliability.

Power Supply Recommendations

Use of Surge Protection

Install surge protection devices to safeguard the NTCL01 module from sudden voltage spikes, lightning strikes, or switching transients.

Stable Voltage and Current

Ensure that the module receives stable voltage and current within ABB specifications. Avoid frequent power cycling, as repeated startups can stress internal components.

Grounding and Bonding

Proper grounding and bonding reduce electrical noise and prevent potential damage caused by static electricity or stray currents, enhancing module reliability.

Operational Guidelines

Load Balancing

Avoid operating the NTCL01 module near its maximum rated capacity continuously. Balanced load usage extends contact life and prevents overheating.

Signal Verification

Regularly check input and output signals for correct operation. Incorrect signal levels can indicate wiring or configuration issues that, if left unaddressed, may damage the module.

Firmware Updates

Keep the module firmware updated to ensure compatibility with automation systems and to benefit from bug fixes and performance improvements. ABB often releases updates that enhance functionality and stability.

Maintenance Strategies

Periodic Inspections

Conduct routine inspections to check for signs of wear, loose connections, or environmental damage. Early detection helps prevent major failures.

Cleaning Procedures

Keep the module free from dust and debris. Use non-conductive brushes or compressed air to gently clean connectors and the housing without opening sensitive components.

Preventive Replacement

Replace worn or aged connectors, cables, or associated components before failure occurs. Proactive replacement prevents unexpected downtime and maintains system reliability.

Environmental Protection Measures

Temperature Management

Maintain ambient temperatures within ABB’s specified range. Overheating can degrade internal components, while extreme cold may cause mechanical stress.

Humidity Control

Install modules in controlled environments or use enclosures with humidity protection. Moisture can cause corrosion and electrical shorts, reducing lifespan.

Vibration Dampening

Use vibration-dampening mounts if the NTCL01 module is installed in high-vibration areas, such as near motors or heavy machinery, to prevent mechanical fatigue.

Diagnostic and Monitoring Practices

Real-Time Monitoring

Integrate the NTCL01 module with monitoring systems to continuously check performance and detect anomalies early.

Alarm Configuration

Configure alarms to notify operators of abnormal voltage, temperature, or signal conditions. Immediate action can prevent module damage.

Logging and Analysis

Maintain logs of module performance, power cycles, and fault events. Historical analysis can identify trends that may threaten long-term reliability.

Training and Personnel Awareness

Operator Training

Ensure that staff handling or maintaining the NTCL01 module understand proper installation, usage, and maintenance procedures.

Safety Procedures

Educate personnel about electrical safety, grounding, and handling static-sensitive electronics to prevent damage during maintenance or installation.

Benefits of Following Proper Usage Tips

Extended Module Lifespan

Following these guidelines significantly extends the NTCL01 module operational life, delaying the need for replacements and reducing capital expenditure.

Enhanced System Reliability

Proper usage minimizes downtime caused by unexpected failures, ensuring consistent operation across industrial automation systems.

Cost Efficiency

Preventive measures and correct handling reduce repair costs, unplanned downtime, and operational interruptions, delivering long-term cost savings.

Optimal Performance

By maintaining environmental stability, balanced loads, and clean connections, the NTCL01 module consistently delivers peak performance and accurate control signals.

Case Studies: Successful Implementation

Manufacturing Plant Scenario

A large manufacturing plant implemented strict installation, power management, and preventive maintenance protocols for ABB NTCL01 modules. Result: 30% reduction in downtime and improved system responsiveness.

Chemical Processing Facility

In a chemical plant, environmental control enclosures and vibration mounts were installed to protect NTCL01 modules. Result: Modules operated flawlessly for over 7 years, with minimal maintenance.

Power Generation Example

A power plant monitored NTCL01 modules via real-time diagnostics, enabling predictive maintenance. Result: Reduced failures and uninterrupted turbine control, ensuring reliable energy production.

Future-Proofing Your ABB NTCL01 Deployment

Scalability

Proper usage allows for seamless addition of modules as automation systems expand, ensuring long-term scalability.

Integration with Digital Systems

Maintaining optimal conditions ensures compatibility with digital automation and Industry 4.0 initiatives, including predictive analytics and smart monitoring.

Sustainability

Extending module lifespan reduces electronic waste and lowers the environmental impact of automation systems, supporting sustainable industrial practices.

Summary

The ABB NTCL01 module is a powerful automation component, and its lifespan and reliability can be significantly enhanced by following proper usage practices. Key strategies include maintaining optimal environmental conditions, ensuring stable power supply, managing loads, performing routine inspections, and following ABB installation guidelines.

By implementing these tips, industrial operators can achieve longer-lasting, highly reliable NTCL01 modules, reducing downtime, minimizing maintenance costs, and ensuring consistent, high-performance operation across diverse industrial applications. Proper care and preventive measures not only protect the investment but also support the efficiency and safety of modern automation systems.

The ABB NTCL01 remains a benchmark for industrial automation reliability when combined with best practices, delivering superior performance, extended lifespan, and dependable operation in complex industrial environments.