Blogs

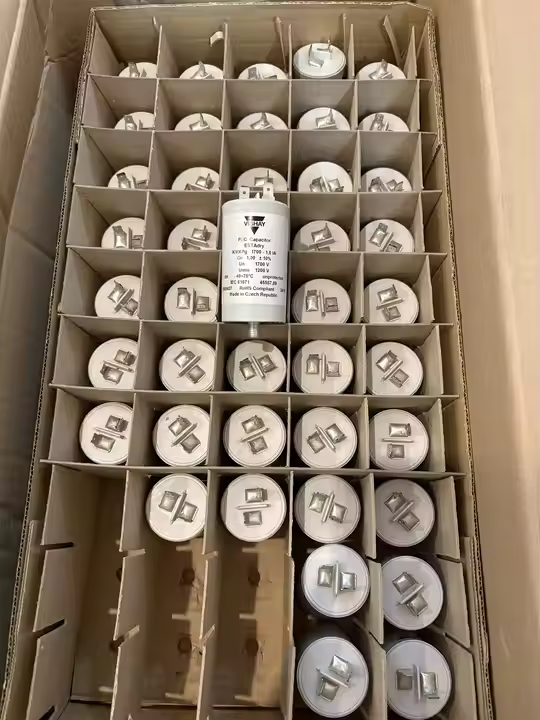

KMKPg1700-1.0IA Capacitor Maintenance Methods for Industrial Applications

The KMKPg1700-1.0IA capacitor plays a crucial role in industrial automation and electrical systems, providing reliable voltage stabilization, energy efficiency, and protection for critical equipment. Regular maintenance ensures its long-term performance, prevents unexpected failures, and reduces downtime. Wuhan Yuli Automation Technology Co., Ltd. supplies high-quality KMKPg1700-1.0IA capacitors and provides guidance for effective maintenance practices.

1. Overview of KMKPg1700-1.0IA Capacitors

KMKPg1700-1.0IA capacitors deliver stable electrical performance across industrial networks. Their primary functions include:

-

Energy Storage: Smoothens voltage fluctuations to protect sensitive equipment.

-

Voltage Stabilization: Ensures continuous, consistent power supply.

-

Power Factor Correction: Reduces energy loss and improves system efficiency.

Due to their critical role, maintaining these capacitors is essential for sustaining industrial process efficiency.

2. Importance of Regular Maintenance

Regular maintenance prevents capacitor failures, which can lead to production downtime and costly equipment damage. By performing routine checks, technicians can detect early signs of wear, overheating, or electrical degradation. Additionally, proper maintenance extends the capacitor’s lifespan and ensures that industrial systems operate reliably and efficiently.

3. Inspection Procedures

3.1 Visual Inspection

Technicians should examine the capacitor for any physical damage, such as cracks, bulging, corrosion, or leakage. Visual inspection helps detect potential issues before they escalate.

3.2 Electrical Testing

Regular testing of capacitance, insulation resistance, and leakage current ensures the capacitor operates within specification. Comparing test results over time identifies gradual performance decline.

3.3 Connection Checks

Check all terminal connections for tightness and corrosion. Loose or oxidized connections can increase resistance, causing overheating and potential failure.

4. Cleaning and Environmental Control

Keeping the capacitor clean and properly ventilated is crucial:

-

Dust Removal: Accumulated dust reduces heat dissipation. Use compressed air to remove dust regularly.

-

Temperature Control: Maintain ambient temperatures within the recommended operating range. Avoid excessive heat, which accelerates aging.

-

Humidity Control: Ensure the environment is dry to prevent moisture penetration that can cause insulation breakdown.

5. Preventive Maintenance Schedule

A structured maintenance schedule increases reliability:

-

Monthly: Visual inspection, dust removal, terminal checks.

-

Quarterly: Electrical testing of capacitance and leakage current.

-

Annually: Comprehensive inspection, including insulation resistance testing and replacement of worn components if necessary.

Following this schedule helps prevent unexpected failures and improves system longevity.

6. Troubleshooting Common Issues

6.1 Overheating

Overheating may result from excessive current, poor ventilation, or loose connections. Resolve by reducing load, improving airflow, and tightening connections.

6.2 Leakage

Leakage indicates deterioration of insulation. Replace the capacitor immediately to prevent system damage.

6.3 Reduced Capacitance

Gradual capacitance decline can affect voltage stabilization. Monitor regularly and replace if values fall below acceptable limits.

7. Safety Considerations

Working with high-voltage capacitors requires strict safety precautions:

-

Power Down: Disconnect the capacitor from the circuit before maintenance.

-

Discharge: Use proper discharge tools to eliminate stored energy.

-

Protective Gear: Wear insulated gloves and eye protection to prevent injury.

Observing these safety protocols ensures technician safety and prevents accidental damage.

8. Integration with Industrial Systems

Properly maintained KMKPg1700-1.0IA capacitors contribute to efficient industrial operations by:

-

Enhancing motor drive efficiency.

-

Reducing reactive power losses in distribution networks.

-

Stabilizing automation control systems, preventing operational errors.

Regular maintenance ensures these benefits remain consistent over time.

9. Role of Wuhan Yuli Automation Technology Co., Ltd.

Wuhan Yuli Automation Technology Co., Ltd. provides high-quality KMKPg1700-1.0IA capacitors and expert guidance for installation and maintenance. Their support helps industries implement best practices, extending capacitor life and maintaining reliable power in complex industrial networks.

10. Conclusion

The KMKPg1700-1.0IA capacitor is vital for industrial applications, supporting energy efficiency, voltage stabilization, and equipment protection. Following structured maintenance procedures—visual inspection, electrical testing, cleaning, and preventive schedules—ensures long-term performance. With professional guidance from Wuhan Yuli Automation Technology Co., Ltd., industries can optimize capacitor reliability, reduce downtime, and maintain safe, efficient operations.