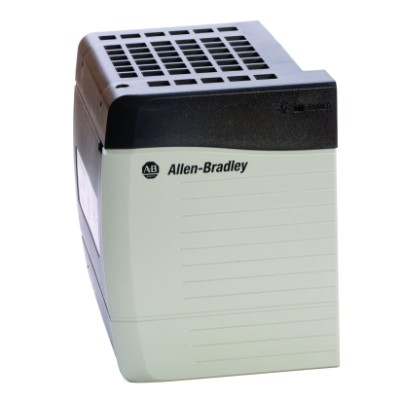

Allen-Bradley 1756-PA72 Power Supply — Stable Energy for ControlLogix Systems

The Allen-Bradley 1756-PA72 Power Supply delivers the stable, efficient, and reliable power that ControlLogix systems require to operate effectively. Manufactured by Rockwell Automation, this unit represents one of the most trusted power solutions in modern industrial control applications. Because automation processes depend on consistent voltage and uninterrupted power, the 1756-PA72 becomes an essential foundation for every reliable control system.

Introduction to the 1756-PA72 Power Supply

The 1756-PA72 serves as a primary power module for the ControlLogix 1756 chassis, which hosts various input/output, communication, and processor modules. It provides regulated 24V DC or 5V DC power internally to all connected modules through the backplane. With an input of 85–265V AC, the unit adapts easily to global industrial standards and ensures seamless integration across diverse facilities.

Because modern industries cannot tolerate downtime, engineers choose the 1756-PA72 for its outstanding voltage regulation, low heat dissipation, and compact design. Every detail in its construction enhances long-term stability, helping automation systems run smoothly in dynamic environments.

Technical Specifications

To understand its value fully, it helps to review the technical characteristics of the 1756-PA72:

-

Catalog Number: 1756-PA72

-

Input Voltage: 85–265V AC

-

Input Frequency: 47–63 Hz

-

Output Voltage: 24V DC (backplane power)

-

Output Current: Up to 13A at 5.1V DC

-

Power Consumption: Approximately 75W typical

-

Chassis Compatibility: 1756-A series chassis

-

Dimensions: Compact standard module size for rack mounting

-

Operating Temperature: 0°C to +60°C

-

Manufacturer: Rockwell Automation

These specifications show how the power supply fits perfectly within ControlLogix architectures, ensuring optimal energy efficiency and performance consistency.

Core Design and Engineering

The Allen-Bradley 1756-PA72 features a robust internal design that minimizes electrical noise while maintaining steady output power. Because industrial controllers operate in environments filled with electrical interference, the power supply’s filtering capabilities protect sensitive logic modules from voltage spikes or fluctuations.

Moreover, the unit includes efficient thermal management, allowing it to maintain optimal operating temperature even under heavy loads. This ensures that the system remains stable without overheating or energy waste.

The design also allows quick installation. Engineers can easily slide it into the chassis and connect it without external wiring modifications. Its modular nature makes it simple to replace or upgrade, reducing system downtime during maintenance or expansion.

How the 1756-PA72 Powers ControlLogix Systems

Every ControlLogix chassis relies on a dedicated power module to distribute regulated voltage across all slots. The 1756-PA72 performs this task with precision. It converts incoming AC power into clean DC energy, which flows through the chassis backplane to energize controllers, communication modules, and I/O units.

Because each component draws power simultaneously, voltage stability matters greatly. The 1756-PA72 maintains consistent output even when multiple modules operate at peak loads. As a result, logic execution, data transfer, and control functions remain uninterrupted.

In addition, this model includes an internal power monitoring feature that alerts users through system diagnostics if any irregularity occurs. This intelligent design helps prevent unplanned shutdowns and simplifies troubleshooting.

Advantages of the Allen-Bradley 1756-PA72

Choosing the 1756-PA72 offers several benefits that make it one of the most trusted power modules for ControlLogix platforms:

-

Stable Output Voltage – It ensures consistent power flow for all modules, even during load fluctuations.

-

Wide Input Range – It operates effectively with both low and high AC voltage sources from 85V to 265V.

-

Compact Size – It fits neatly into ControlLogix chassis without requiring extra space.

-

Energy Efficiency – It minimizes power loss and reduces overall operating costs.

-

Quick Installation – It connects directly to the backplane, simplifying setup and system integration.

-

Durable Construction – It withstands vibration, electrical noise, and thermal stress in industrial environments.

Because of these features, engineers across manufacturing, energy, and process industries continue to rely on this power supply for mission-critical systems.

Applications Across Industries

The 1756-PA72 Power Supply supports automation systems across multiple sectors. For instance, manufacturing plants use it to power production lines and robotic control units. Energy facilities depend on it for process monitoring and equipment control. Water treatment plants employ it to maintain consistent operation of pumps, sensors, and control units.

In addition, industries such as automotive, pharmaceuticals, and food processing also benefit from its reliable voltage control. Wherever continuous operation and precise control matter, the 1756-PA72 delivers dependable performance.

Installation and Operation

Installing the Allen-Bradley 1756-PA72 is straightforward. First, engineers mount the module into the appropriate slot on the ControlLogix chassis. Then, they connect the AC input power leads according to wiring diagrams provided by Rockwell Automation. After powering up, the unit immediately supplies energy to the backplane, enabling all installed modules to function.

During operation, users can observe LED indicators on the module that show power status and fault conditions. Because the unit integrates seamlessly with Rockwell Automation software tools, system diagnostics remain simple and efficient.

To ensure optimal performance, engineers should maintain clean ventilation around the chassis and monitor environmental conditions. Keeping the system within recommended temperature ranges guarantees long-term reliability.

Maintenance and Safety

Although the 1756-PA72 requires minimal maintenance, regular inspection ensures consistent performance. Technicians should check power connections periodically, verify LED status, and confirm that the chassis cooling system operates efficiently.

For safety, always disconnect input power before performing any maintenance tasks. Because the power supply stores residual energy, waiting a few seconds after power-off allows internal capacitors to discharge fully.

Additionally, following Rockwell Automation’s safety documentation guarantees proper handling and installation procedures. Consistent maintenance not only extends the unit’s lifespan but also prevents potential power interruptions.

Performance and Efficiency

One of the major strengths of the Allen-Bradley 1756-PA72 lies in its energy efficiency. Because the unit converts AC to DC with minimal power loss, it reduces energy costs and heat output. This efficiency also improves system sustainability by lowering the overall environmental footprint of the automation system.

Moreover, its design enhances power quality by reducing electrical noise and harmonic distortion. As a result, connected modules operate with higher accuracy and reliability. The stable voltage ensures smooth controller operations and prevents unpredictable resets or communication faults.

Partnering with Wuhan Yuli Automation Technology Co., Ltd.

To ensure authentic sourcing and reliable support, Wuhan Yuli Automation Technology Co., Ltd. supplies original Allen-Bradley 1756-PA72 power modules. As a trusted automation component distributor, Wuhan Yuli provides professional technical advice, quality assurance, and responsive service for customers worldwide.

Their expertise in Rockwell Automation products helps industries maintain efficiency and reliability across their control systems. Partnering with a certified supplier also ensures access to replacement parts, technical documentation, and after-sales support whenever needed.

Conclusion

In summary, the Allen-Bradley 1756-PA72 Power Supply offers a perfect combination of reliability, efficiency, and easy integration for ControlLogix systems. Its broad input range, stable output, and robust design make it ideal for demanding industrial environments. Because automation systems rely on consistent power delivery, this module serves as the backbone for continuous operation and data integrity.

When industries demand performance, the 1756-PA72 delivers. Its proven track record, energy efficiency, and seamless compatibility with Rockwell’s architecture make it the preferred choice for engineers who value dependability.

For genuine products and professional service, Wuhan Yuli Automation Technology Co., Ltd. remains your trusted partner in industrial automation excellence.

Related products

Products

Products

Products

Products

Products

Products

Products

Products