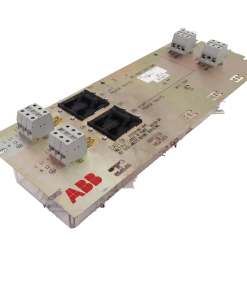

ABB Pneumatic Actuator LP10BB10010: A Reliable and Efficient Actuation Solution for Industrial Automation

In the world of industrial automation, precision and reliability are paramount. Systems across various industries require efficient and consistent actuation to ensure the smooth functioning of processes. The ABB Pneumatic Actuator LP10BB10010 is an ideal solution for achieving these goals. Designed to offer high performance, energy efficiency, and durability, this actuator excels in controlling valves, dampers, and other critical mechanical components. Whether used in power plants, chemical processing, or manufacturing facilities, the LP10BB10010 delivers exceptional control and reliability.

In this article, we will delve into the features, technical specifications, applications, and benefits of the ABB Pneumatic Actuator LP10BB10010, and explain why it stands out as a trusted choice for industries that demand precision actuation and enhanced efficiency.

1. Introduction to the ABB Pneumatic Actuator LP10BB10010

The ABB Pneumatic Actuator LP10BB10010 is a robust and efficient solution for controlling mechanical systems in industrial environments. Operating on compressed air, this actuator provides the necessary force to drive mechanical movements, such as opening or closing valves, adjusting dampers, and controlling other moving parts. Its ability to provide precise control and high-speed operation makes it an indispensable component in industries where time-sensitive adjustments are critical.

The LP10BB10010 actuator is designed to integrate seamlessly into existing industrial systems, offering both flexibility and reliability. With its advanced features and energy-efficient performance, the actuator supports industries in improving operational efficiency while reducing energy costs and downtime.

2. Key Features of the ABB Pneumatic Actuator LP10BB10010

High Force Output

The LP10BB10010 actuator is designed to provide high torque and force output. This allows it to control large or heavy mechanical components, such as valves in demanding industrial environments. Whether controlling the flow of liquids, gases, or chemicals, the actuator ensures that valves and dampers operate smoothly under varying pressures. This capability helps maintain system stability and ensures reliable operation of the entire process.

Compact and Rugged Design

Despite its high-performance capabilities, the LP10BB10010 actuator has a compact and lightweight design, making it suitable for applications where space is limited. Its rugged construction ensures that it can withstand harsh environmental conditions, including exposure to extreme temperatures, moisture, and chemicals. The actuator’s ability to function reliably in tough environments makes it ideal for use in offshore rigs, chemical plants, and other high-demand sectors.

Energy Efficiency

The LP10BB10010 is designed to be energy-efficient, which makes it an excellent choice for industries seeking to reduce energy consumption and operational costs. The actuator uses compressed air to generate mechanical motion, which typically requires less energy compared to other types of actuators, such as electric actuators. By minimizing energy consumption, the LP10BB10010 helps companies achieve sustainability goals and maintain cost-effective operations over the long term.

High-Speed Operation and Precision Control

One of the standout features of the LP10BB10010 actuator is its high-speed operation, making it suitable for applications where fast response times are essential. Whether adjusting the position of a valve or controlling flow rates, the actuator operates with speed and precision, helping industries maintain consistent performance and system stability. Its precision control ensures that even slight adjustments are made accurately, avoiding system fluctuations that could compromise efficiency.

Corrosion-Resistant and Durable

The LP10BB10010 actuator features corrosion-resistant materials that enable it to function reliably even in harsh and corrosive environments. The actuator is built to resist the damaging effects of exposure to chemicals, water, and extreme weather conditions. This ensures long-term durability, even in industries like oil and gas, where equipment is subjected to challenging operating environments.

Easy Integration and Maintenance

The actuator’s modular design ensures that it can be easily integrated into existing industrial systems. Additionally, its simple structure and user-friendly maintenance features help minimize downtime and reduce maintenance efforts. When maintenance is required, the LP10BB10010 actuator’s parts are easy to access, and the process can be performed with minimal disruption to ongoing operations.

3. Technical Specifications of the ABB Pneumatic Actuator LP10BB10010

| Parameter | Specification |

|---|---|

| Model Number | ABB Pneumatic Actuator LP10BB10010 |

| Actuator Type | Double-acting Pneumatic Actuator |

| Torque Output | 30 to 80 Nm |

| Air Consumption | 0.08 to 0.20 Nm³/min at 6 bar |

| Operating Pressure Range | 2 to 8 bar (29 to 116 psi) |

| Mounting Type | Flange-mounted with standard bolt patterns |

| Body Material | Corrosion-resistant anodized aluminum alloy |

| Temperature Range | -20°C to +80°C |

| Weight | 5.5 kg |

| Protection | IP65 (dustproof and water-resistant) |

| Seals | Elastomer seals resistant to chemicals and wear |

| Certifications | CE, ATEX, UL |

4. Applications of the ABB Pneumatic Actuator LP10BB10010

The LP10BB10010 pneumatic actuator is used across a variety of industries, thanks to its versatility, efficiency, and performance. Below are the key sectors where it is most commonly used:

Oil and Gas

In the oil and gas industry, the LP10BB10010 actuator is used to control valves that regulate the flow of gas, oil, and other fluids. It is critical in controlling pipelines, regulating pressure, and ensuring safe operation in upstream, midstream, and downstream applications. Its corrosion-resistant design makes it ideal for offshore platforms and remote drilling sites, where harsh conditions demand durable, high-performance equipment.

Chemical Processing

Chemical plants rely on the LP10BB10010 actuator for regulating the flow of chemicals, gases, and liquids within reactors, pipelines, and storage tanks. The actuator’s precise control ensures the safety and stability of chemical reactions, while its corrosion resistance ensures long-lasting performance even in aggressive environments.

Water Treatment

The LP10BB10010 actuator is used extensively in water treatment facilities to control valves and dampers. It regulates the flow of water and chemicals, ensuring the treatment process is effective and efficient. The actuator’s high-speed operation and reliable performance make it ideal for the continuous, high-demand environment of water treatment plants.

Power Generation

In power plants, the LP10BB10010 actuator controls valves and dampers in systems that manage fuel, water, and exhaust gases. By maintaining consistent flow rates and pressures, the actuator helps ensure optimal power generation efficiency and safety. Its energy efficiency also reduces operating costs, making it an excellent choice for energy-conscious operations.

Manufacturing

In the manufacturing sector, the LP10BB10010 actuator regulates the flow of materials in automated systems, controls conveyor speeds, and adjusts other mechanical systems. Its compact design and high force output make it suitable for various manufacturing processes, helping improve production efficiency and reduce manual labor.

5. Benefits of the ABB Pneumatic Actuator LP10BB10010

Efficiency and Cost Savings

The LP10BB10010 actuator’s energy-efficient design helps industries save on operating costs. By using compressed air, it minimizes energy consumption while delivering high performance. This makes it a cost-effective choice for industrial automation systems, helping businesses lower their long-term operational costs.

Reliable Performance in Harsh Environments

Thanks to its rugged construction and corrosion-resistant materials, the LP10BB10010 actuator provides reliable performance even in extreme conditions. Whether used in high-pressure systems, offshore platforms, or chemical plants, this actuator withstands the most demanding environments, reducing the risk of failure and downtime.

Improved System Control

With precise control and fast response times, the LP10BB10010 actuator ensures that systems operate with minimal fluctuations. This precise actuation helps maintain system stability, which is crucial in industries that require tight control over variables like temperature, pressure, and flow.

Long-Term Durability

The LP10BB10010 actuator’s durable materials and simple design ensure long-lasting performance. Its modular construction and easy-to-replace components make maintenance simple, reducing downtime and ensuring that the actuator continues to function optimally for years.

6. Conclusion

The ABB Pneumatic Actuator LP10BB10010 provides a reliable, energy-efficient, and high-performance solution for industrial actuation. Its rugged design, precise control, and low energy consumption make it an ideal choice for industries that require reliable and efficient valve control. Whether used in oil and gas, chemical processing, power generation, or manufacturing, the LP10BB10010 actuator helps improve operational efficiency, reduce costs, and enhance system reliability.

By offering excellent performance in demanding environments, the LP10BB10010 is a trusted tool for industries looking to optimize their operations and reduce maintenance costs. With its flexibility and adaptability, this actuator is sure to meet the needs of a wide range of applications.

Be the first to review “LP10BB10010” Cancel reply

Related products

Products

Products

Products

Products

Products

Products

Products

Reviews

There are no reviews yet.