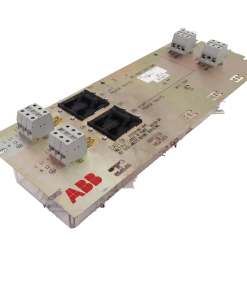

QN33A05HDM

The STONEL QN33A05HDM position switch exemplifies precision, durability, and adaptability in industrial automation. As industries increasingly rely on automated processes, engineers require devices that provide accurate real-time feedback, visual confirmation, and consistent long-term performance. The QN33A05HDM meets these expectations by integrating a rugged enclosure, precise switching mechanism, and flexible electrical options. Its design allows seamless integration into a wide variety of process systems, from chemical plants to water treatment facilities and oil and gas refineries.

Durable Mechanical Design

The QN33A05HDM belongs to the STONEL Quartz series, which emphasizes strong mechanical architecture and long-term reliability. Its reinforced housing resists vibration, mechanical impact, and exposure to harsh chemicals. Because industrial valves often operate under extreme conditions, this model maintains accurate feedback regardless of temperature variations, humidity, or corrosion. The enclosure includes secure seals and a robust cover, which allow technicians to access internal components without compromising protection. Consequently, the QN33A05HDM ensures uninterrupted monitoring and reduces maintenance issues.

Clear Visual Feedback

Operators need immediate visual indication of valve status to ensure process safety. Therefore, the QN33A05HDM features a high-visibility, color-coded dome indicator that clearly shows OPEN or CLOSED positions. The indicator remains legible under sunlight, low-light conditions, and during long-term use. Its design minimizes dust accumulation and resists fading over time. Because operators can quickly confirm valve positions from a distance, the visual feedback enhances situational awareness and supports faster decision-making in both routine operations and emergency scenarios.

Flexible Electrical Configuration

The QN33A05HDM accommodates a variety of switch types, including mechanical snap-action switches and proximity sensors, enabling compatibility with different control systems. Engineers can configure terminal arrangements to match plant wiring requirements, which simplifies installation and reduces wiring errors. Its electrical components maintain precise signal output even in high electromagnetic interference environments. Since industrial facilities often operate complex control systems, this flexibility allows for seamless integration with PLCs, DCS platforms, and other automation infrastructure.

Seamless Integration with Actuators

This model supports standard actuator mounting patterns, making installation straightforward on quarter-turn and rotary valves. The internal linkage follows actuator movement with high precision, delivering accurate end-position detection. Engineers can rely on the QN33A05HDM to provide consistent feedback over repeated cycles, even in high-frequency operations. The precise alignment reduces wear on internal components and ensures reliable operation, which ultimately contributes to the overall efficiency of the automation system.

Environmental Resistance and Longevity

Industrial environments expose devices to extreme conditions, including temperature fluctuations, chemical exposure, and moisture. The QN33A05HDM resists corrosion, UV radiation, and mechanical stress due to its reinforced materials and engineering-grade seals. Its durability makes it suitable for outdoor installations and harsh industrial settings. Operators benefit from consistent performance without frequent recalibration, which reduces maintenance costs and ensures uninterrupted process control.

Enhanced Safety

Process safety remains a key priority, and the QN33A05HDM enhances it by providing reliable, real-time valve status information. Its precise switching action ensures accurate communication with interlocks and emergency shutdown systems. Technicians can monitor operations confidently, knowing that the switch delivers correct feedback. The device’s robust enclosure also protects internal components from accidental damage, contributing to safer plant operations.

Industrial Applications

The QN33A05HDM suits a wide range of industries. Chemical plants use it to monitor reactive valves, while oil and gas facilities integrate it into pipeline isolation systems. Water treatment plants rely on it for filtration and dosing valves, and pharmaceutical and food processing plants benefit from its resistance to wash-down operations. Across all these applications, the QN33A05HDM delivers dependable feedback and enhances automation efficiency. Its versatility makes it an ideal solution for facilities requiring precise valve monitoring in challenging environments.

Efficient Commissioning and Maintenance

The QN33A05HDM simplifies installation, commissioning, and routine maintenance. The terminal layout and internal component organization allow technicians to complete wiring and inspections quickly. Since the device maintains stable operation over long periods, maintenance intervals extend, minimizing plant downtime. The design focuses on ease of access and clarity, so technicians perform adjustments and troubleshooting efficiently, which improves overall operational productivity.

Return on Investment

The QN33A05HDM offers long-term value by reducing downtime, maintenance costs, and equipment replacement frequency. Its durable construction and flexible integration capabilities enhance reliability, while accurate feedback ensures smooth operation of automation systems. Because the device maintains consistent performance in diverse conditions, engineers can optimize their processes, reduce operational risk, and achieve a high return on investment.

⭐ Summary

The STONEL QN33A05HDM position switch provides high-precision valve monitoring, rugged durability, and flexible integration. Its clear visual indication, adaptable electrical configuration, and actuator compatibility make it suitable for chemical, oil and gas, water treatment, pharmaceutical, and food processing industries. Engineers rely on its consistent performance and robust design to ensure operational efficiency, safety, and long-term reliability in demanding industrial environments.

Related products

Products

Products

Products

Products

Products

Products

Products

Products