Blogs

ABB SPDSI13 Module and PLC Control System Compatibility

Introduction

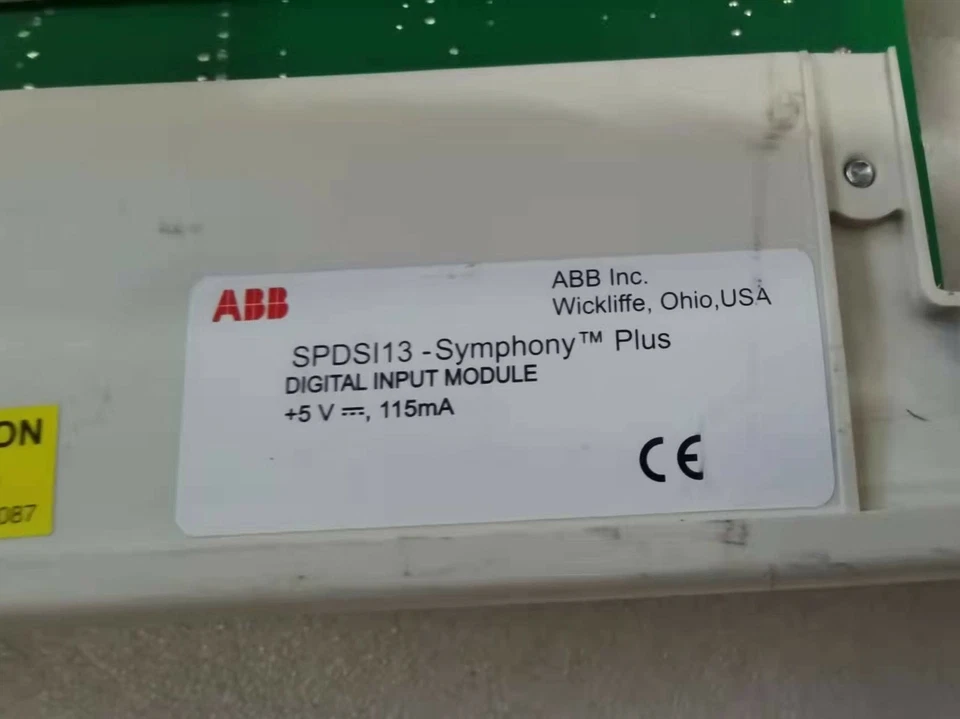

The ABB SPDSI13 module serves as a vital component in modern industrial automation. Its integration with PLC control systems ensures precise signal acquisition, real-time processing, and efficient system communication. Many industrial operators face challenges understanding which PLC systems are fully compatible with SPDSI13, yet achieving seamless integration is essential for stable and efficient operation.

Wuhan Yuli Automation Technology Co., Ltd. (website: www.wuhanyuli.com) provides professional solutions for ABB modules, including SPDSI13, helping customers optimize compatibility and maintain reliable industrial automation systems.

This article explores SPDSI13 module compatibility with PLC systems, key factors influencing integration, and practical guidelines for industrial implementation.

Understanding ABB SPDSI13 Module Functions

Before examining compatibility, one must understand SPDSI13 functionalities. The module supports digital and analog I/O, logic processing, and communication with central control units. It performs real-time data analysis and transfers signals accurately, ensuring that industrial processes operate smoothly.

The module’s capabilities include:

-

Multi-channel signal acquisition

-

High-speed logic computation

-

Communication over standard industrial buses

-

Safety monitoring and system diagnostics

By recognizing these functionalities, operators can determine how SPDSI13 aligns with their existing PLC architecture.

Key Compatibility Factors with PLC Systems

Electrical Specifications

ABB SPDSI13 modules require precise voltage and current levels to function correctly. Ensuring that the PLC power supply matches the module’s specifications is critical. Mismatched voltage levels can lead to signal errors or system instability.

Communication Protocols

SPDSI13 supports various industrial communication protocols such as Profibus, Modbus, and ABB-specific fieldbus standards. Selecting a PLC that supports these protocols guarantees seamless data exchange and reduces integration complexity.

Slot and Connector Compatibility

The physical installation of SPDSI13 depends on standard backplane slots. Verify that the PLC or rack system accommodates the module’s size, pin layout, and insertion mechanism. Correct installation prevents electrical shorts and ensures proper module engagement.

Software and Firmware Integration

PLC programming software must recognize SPDSI13 and its I/O mapping. Firmware versions should align with both the PLC and module to maintain system performance and avoid unexpected errors.

Practical Guidelines for Integration

Step 1: Assess Existing PLC System

Analyze your current PLC architecture. Determine the number of available slots, supported communication protocols, and input/output requirements. Understanding these parameters ensures that SPDSI13 integration will meet operational needs.

Step 2: Verify Module Specifications

Check SPDSI13 specifications against system requirements. Confirm signal type, channel count, power needs, and environmental tolerance. Matching these parameters avoids compatibility issues during deployment.

Step 3: Perform Pre-installation Testing

Conduct simulation tests in a controlled environment. Connect SPDSI13 to the PLC in a test rack to verify communication, signal integrity, and logic execution. Pre-installation testing prevents production downtime.

Step 4: Installation and Configuration

Insert the SPDSI13 module into the designated slot and connect field devices. Use ABB-approved wiring diagrams and ensure secure connections. Configure PLC software to recognize module channels and establish communication parameters.

Step 5: Monitor System Performance

After installation, continuously monitor signals, data flow, and response times. Identify any latency or communication errors and adjust configuration parameters as needed.

Advantages of Ensuring Compatibility

-

System Reliability

Fully compatible modules reduce errors and prevent system crashes. -

Operational Efficiency

Seamless integration ensures faster response times and better process control. -

Reduced Maintenance Costs

Properly integrated modules require less troubleshooting and reduce downtime. -

Safety Assurance

Compatibility ensures accurate monitoring and rapid fault detection, enhancing workplace safety. -

Future Expandability

Modules aligned with PLC standards allow easy system expansion without redesigning infrastructure.

Common Challenges and Solutions

Signal Errors

Signal mismatches often occur when voltage or communication protocol settings differ. Using ABB-recommended power supplies and confirming protocol compatibility solves most issues.

Installation Errors

Improper slot selection or loose connections can disrupt communication. Carefully follow ABB installation guidelines and verify mechanical fit.

Firmware Incompatibility

Outdated firmware may prevent the PLC from recognizing SPDSI13 modules. Keep firmware versions updated for both PLC and module.

Environmental Concerns

Extreme temperatures, dust, or electromagnetic interference can affect module performance. Ensure installation in suitable industrial environments and apply protective measures.

Case Studies of Successful Integration

-

Chemical Plant Automation

SPDSI13 integrated into PLC-controlled pump and valve systems improved process stability and reduced manual intervention by 30%. -

Metallurgical Process Control

Rolling mill automation benefited from SPDSI13 real-time signal processing, enhancing product consistency and minimizing downtime. -

Water Treatment Facility

Integration of SPDSI13 with PLCs enabled accurate monitoring of flow, pressure, and valve operations, ensuring regulatory compliance and operational safety.

Best Practices for Long-Term Compatibility

-

Maintain consistent software and firmware updates

-

Use original ABB SPDSI13 modules for guaranteed reliability

-

Schedule periodic inspections of wiring, connectors, and system signals

-

Collaborate with professional suppliers like Wuhan Yuli Automation Technology Co., Ltd. (www.wuhanyuli.com) for support and spare parts

-

Document system configuration and keep detailed logs for troubleshooting

Conclusion

ABB SPDSI13 modules provide robust functionality and play a critical role in industrial automation systems. Ensuring compatibility with PLC control systems enhances reliability, operational efficiency, and safety. By following careful selection, installation, and maintenance practices, operators can maximize module performance and extend system longevity.

Wuhan Yuli Automation Technology Co., Ltd. provides original SPDSI13 modules, technical guidance, and integration support, helping industrial clients maintain fully compatible and efficient automation systems.