Blogs, Product Installation Guide

The Ultimate Guide to the VISHAY KMKPg1700 Film Capacitor: Ensuring Reliability in ABB Drive Systems

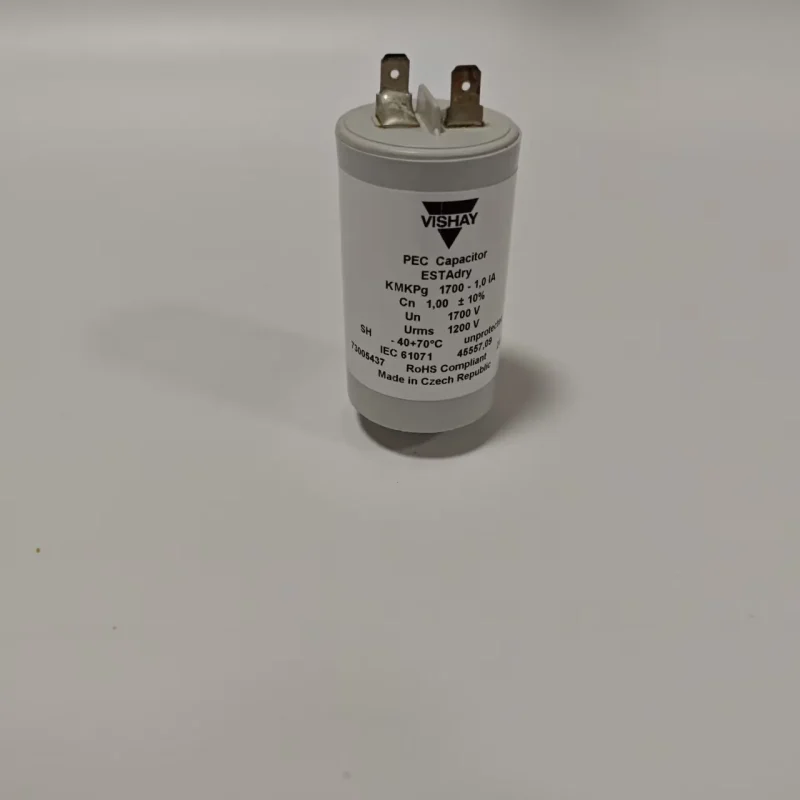

In the complex ecosystem of industrial automation, the integrity of every component is paramount. At the heart of many mission-critical systems, particularly those powered by ABB drives, lies a component whose failure can bring entire production lines to a halt: the capacitor. Not all capacitors are created equal. When seeking a VISHAY film capacitor for a high-demand application, the VISHAY KMKPg1700 series often emerges as the premier choice. This deep-dive blog post explores why this specific capacitor is so critical, especially when used as a genuine ABB (ABB drive spare part), ensuring peak performance, reliability, and longevity for your industrial assets.

Understanding the Critical Role of Capacitors in ABB Drives

ABB variable frequency drives (VFDs) are the workhorses of modern industry, controlling the speed and torque of electric motors with unparalleled precision. From controlling pumps in water treatment facilities to managing conveyor belts in manufacturing plants, these drives are subjected to rigorous electrical stresses.

Inside an ABB drive, capacitors serve several vital functions, with one of the most demanding being the snubber circuit. Let’s break down what this means:

-

The Problem of Voltage Spikes: When the drive’s Insulated Gate Bipolar Transistors (IGBTs) switch on and off thousands of times per second, they create rapid changes in current (di/dt). This phenomenon, due to circuit inductance, generates massive voltage spikes that can far exceed the IGBT’s rated voltage, leading to premature failure.

-

The Snubber Solution: A snubber circuit, typically a resistor and capacitor in series, is placed directly across the IGBT. Its job is to “snub” or dampen these voltage spikes, absorbing the surge energy and protecting the expensive semiconductor.

-

Why the Capacitor is Key: The capacitor in this snubber circuit must be exceptionally robust. It must charge and discharge incredibly quickly, handle high peak currents, and withstand continuous high-frequency pulse stress without degrading.

Using a generic, off-the-shelf capacitor in this role is a recipe for downtime. The component requires a specific set of characteristics—precisely what the VISHAY KMKPg1700 film capacitor is engineered to provide.

Deep Dive: The VISHAY KMKPg1700 Film Capacitor – A Technical Powerhouse

When you specify a VISHAY 电容 KMKPg1700, you are not just buying a capacitor; you are investing in a meticulously engineered component designed for survival and performance. Let’s analyze the key features that make it stand out.

1. Superior Dielectric Material: Metalized Polypropylene Film

The foundation of any film capacitor is its dielectric. The KMKPg1700 uses metalized polypropylene, a material chosen for its exceptional electrical properties:

-

Low Dissipation Factor (DF): This measures the power lost as heat within the capacitor. A very low DF, as found in this series, means higher efficiency, less self-heating, and greater stability over a wide frequency and temperature range. This is crucial for the energy-intensive environment inside a drive.

-

Excellent Dielectric Strength: Polypropylene can withstand high electric fields, making it ideal for the 1700VDC rating of the KMKPg1700-1.0IA model, ensuring it can handle the operational voltage and transient spikes.

2. The “Self-Healing” Property: Built-In Redundancy

This is a game-changer for reliability. If a tiny impurity in the dielectric causes a localized breakdown (a short circuit), the immense current density at the fault point vaporizes the thin metalized electrode around it. This effectively isolates the fault, and the capacitor continues to function, albeit with a negligible loss of capacitance. This self-healing mechanism prevents catastrophic failures and significantly extends the operational life of the component, a non-negotiable feature for a critical ABB 传动 配件 电容.

3. High Pulse Handling Capability and Low ESR/ESL

The KMKPg1700 is specifically designed as a pulse capacitor.

-

Pulse Current Rating: It can withstand the repeated, high-amplitude current surges seen in snubber applications without performance degradation.

-

Low Equivalent Series Resistance (ESL): The non-inductive, extended foil construction minimizes internal inductance. Low ESL allows the capacitor to respond almost instantaneously to fast transients, which is exactly what is needed to clamp a voltage spike effectively.

-

Low Equivalent Series Resistance (ESR): Low ESR works in tandem with low ESL to minimize internal power losses (I²R losses), which in turn reduces heat generation and improves overall efficiency.

4. Ruggedized Construction for Industrial Environments

Unlike consumer-grade components, the VISHAY film capacitor KMKPg1700 is built to last:

-

Flame-Retardant Case (UL 94 V-0): The epoxy-coated case is self-extinguishing, providing a critical safety margin in the event of a severe system fault.

-

Robust Environmental Sealing: Protects the internal film element from moisture and contaminants, ensuring stable performance even in non-climate-controlled industrial settings.

-

Wide Operating Temperature Range: It is designed to perform reliably across a broad temperature spectrum, consistent with the operating conditions inside an ABB drive cabinet.

Why the KMKPg1700 is the Ideal ABB 传动 配件 电容 (ABB Drive Spare Part)

When maintaining or repairing a critical asset like an ABB drive, the choice of spare parts should never be taken lightly. Here’s why the VISHAY KMKPg1700 is more than just a compatible part—it’s an upgrade in reliability.

1. Guaranteed Performance and System Integrity

ABB drives are designed with precise electrical characteristics in mind. Replacing an original snubber capacitor with a sub-par alternative can lead to:

-

Inadequate Protection: A capacitor with insufficient pulse handling capability will degrade quickly, failing to protect the IGBTs and leading to their costly failure.

-

Increased Losses and Heat: A higher ESR capacitor will generate more heat, raising the internal temperature of the drive and potentially stressing other components, reducing the overall system’s lifespan.

-

Unexpected Downtime: The self-healing property of a high-quality capacitor like the KMKPg1700 provides a safety margin. A generic capacitor is more likely to fail short-circuited, causing an immediate and unplanned shutdown.

By using the VISHAY KMKPg1700, you are ensuring that the drive’s protection circuits function exactly as intended, preserving the health of the drive’s most expensive components.

2. The Cost of Downtime vs. The Cost of Quality

The price of a premium VISHAY film capacitor is negligible compared to the cost of industrial downtime. A single production halt in a manufacturing plant can cost thousands of dollars per hour. When a drive fails, the expenses cascade:

-

Cost of emergency troubleshooting and repair.

-

Cost of replacement parts (now including more expensive IGBTs).

-

Cost of lost production.

-

Potential cost of scrap material and missed deadlines.

Investing in a proven, high-reliability component like the KMKPg1700 is a proactive, cost-effective strategy for maximizing Mean Time Between Failures (MTBF).

3. Sourcing and Cross-Referencing

For maintenance managers, the term ABB 传动 配件 电容 is a practical starting point for a search. It’s common for original snubber capacitors in ABB drives to be sourced from premium manufacturers like VISHAY. The KMKPg1700 series, with its specific voltage and capacitance values (like the 1700V, 1.0µF KMKPg1700-1.0IA), is often a direct or superior replacement for OEM parts. When procuring spares, always cross-reference the original part’s specifications with the KMKPg1700’s datasheet to ensure a perfect match or a performance upgrade.

Real-World Application Scenarios

The combination of ABB drives and VISHAY KMKPg1700 capacitors is prevalent across industry:

-

Metal Processing: In rolling mills and presses, drives face extreme load variations. The KMKPg1700 snubber capacitors ensure the IGBTs are protected during rapid acceleration and deceleration, preventing failure in a high-value process.

-

Water & Wastewater: High-power pump drives in treatment plants run continuously. The long-term reliability and self-healing properties of the VISHAY 电容 KMKPg1700 are essential for minimizing maintenance interventions in these critical infrastructure applications.

-

Mining and Minerals: Crushers and conveyor drives operate in dusty, high-vibration environments. The rugged construction of the KMKPg1700 ensures it can withstand these physical challenges while performing its electrical protection duties flawlessly.

Conclusion: Don’t Gamble with Critical Components

In the realm of industrial automation, reliability is engineered, not accidental. The synergy between a robust system like an ABB drive and a high-performance component like the VISHAY KMKPg1700 film capacitor is a testament to this principle. When you are looking for a reliable ABB 传动 配件 电容, looking beyond the generic and opting for a technologically advanced solution is the only prudent choice.

The VISHAY KMKPg1700 is not merely a spare part; it is an insurance policy for your drive, your production line, and your bottom line. Its advanced design, featuring self-healing technology, high pulse handling, and rugged construction, makes it the definitive choice for engineers and maintenance professionals who refuse to compromise on quality and uptime.

Ready to specify the best? Consult the official VISHAY datasheets for the KMKPg1700 series and contact your authorized distributor to ensure you are getting genuine, high-performance components for your next ABB drive maintenance cycle.